CONCRETE POLISHING COUNCIL POLISHED CONCRETE AGGREGATE EXPOSURE CHART

CONCRETE POLISHING COUNCIL POLISHED CONCRETE AGGREGATE EXPOSURE CHART

REPLACES CPAA AGGREGATE EXPOSURE CHART

Download PDF File

CLASS

NAME

SURFACE EXPOSURE, %

A

Cement Fines

85 – 95 % Cement Fines

5 – 15 % Fine Aggregate

B

Fine Aggregate

85 – 95 % Fine Aggregate

5 – 15 % Blend of Cement Fines and Coarse Aggregate

C

Coarse Aggregate

80 – 90 % Coarse Aggregate

10 – 20 % Blend of Cement Fines and Fine Aggregate

Aggregate exposure class denotes the surface exposure after grinding and polishing operations. The density, size and distribution of the aggregates at the surface depends on the concrete mix design and placing and fin- ishing operations. Floor flatness at the time of grinding and polishing operations is an important consideration in selecting the appropriate aggregate exposure class.

Surface exposure percentages are based on visual observation of the overall area of the polished floor.

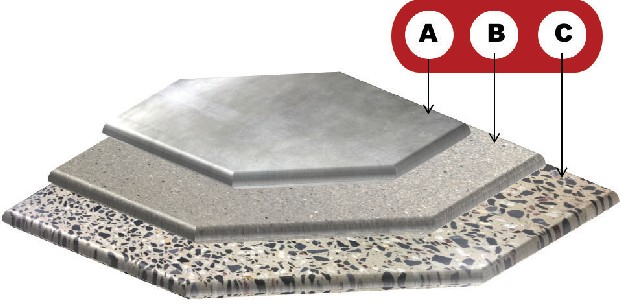

Illustration of Differences in Class

Caution: This provides a visual representation of the differences in Class A, B and C. This may not represent the polished concrete in your area as it varies based on aggregate type, gradation, size and distribution. Consult with your CPC Polishing Contractor to see reference samples or mockups.

Contact your Concrete Polishing Council (CPC) contractor or the CPC Hotline at (844) 923-4678 or by email at cpchotline@ascconline.org with any questions.

PCAEC – 11.17 AMERICAN SOCIETY OF CONCRETE CONTRACTORS